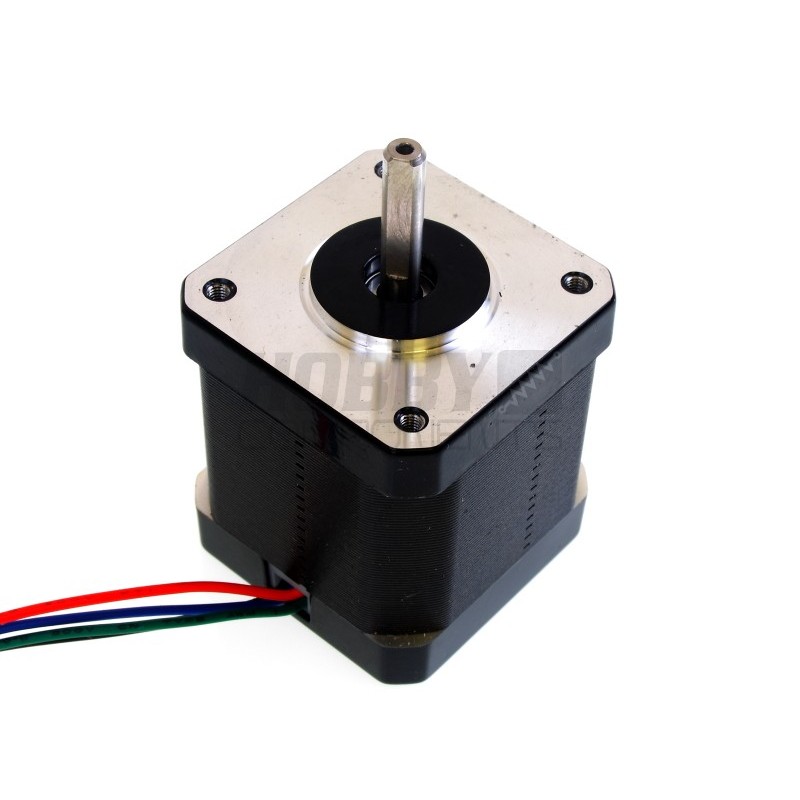

Motor

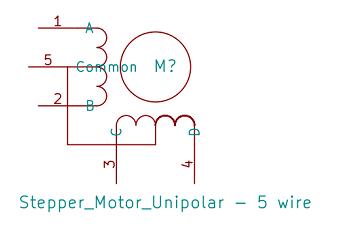

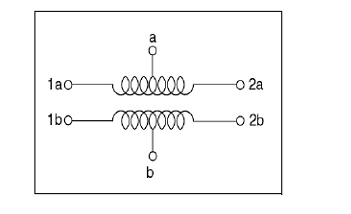

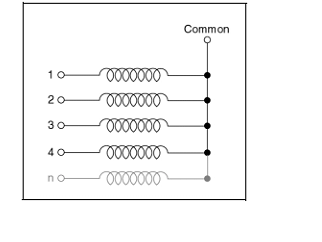

Unipolar stepper motor

Figure 1. Unipolar Stepper Motors Coils

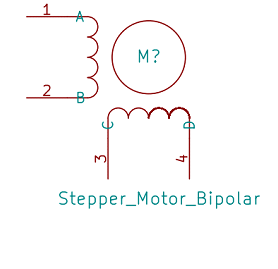

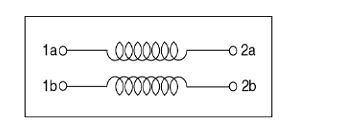

Bipolar Stepper Motor

Figure 2. Bipolar Stepper Motor Coils

Figure 3. Hybrid Stepper Motor Coils

Step Angle

Driving Unipolar Stepper Motors

Full Step

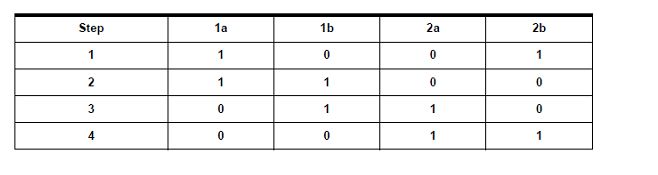

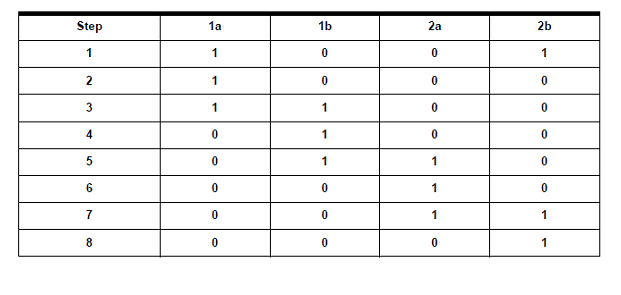

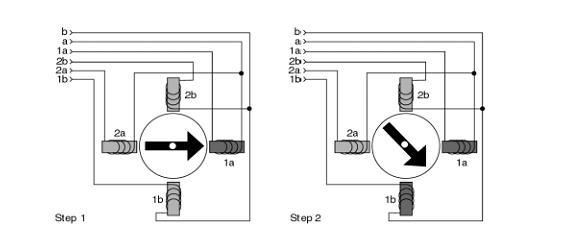

Table 1. One Phase on Sequence

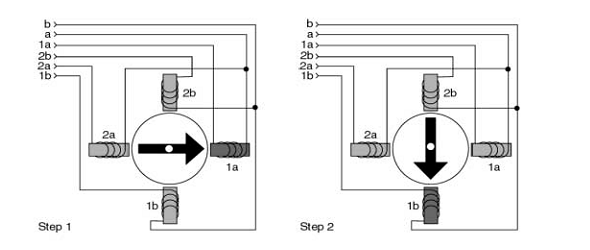

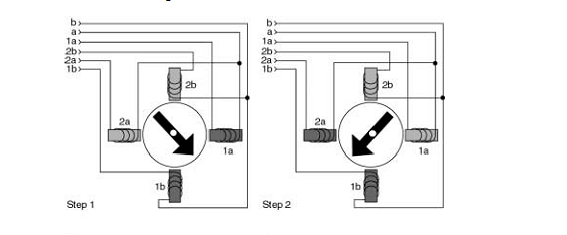

Figure 4. One Phase Steps

Figure 5. One Phase on Steps Sequence

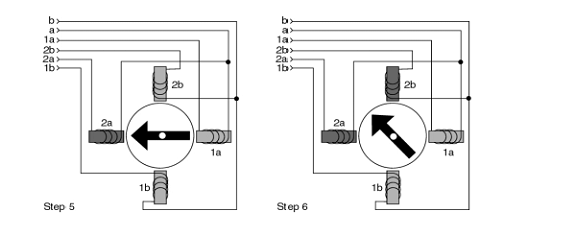

Two Phases on Mode (Alternate Full step Mode)

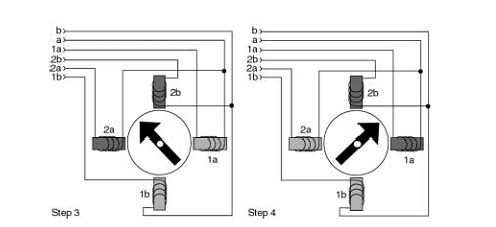

Figure 6. Two Phases on Steps

Figure 7. Two Phases on Steps Sequence

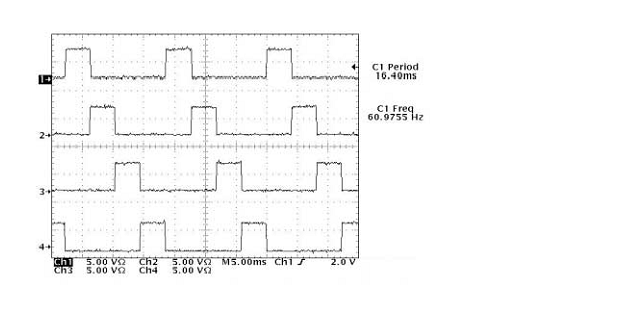

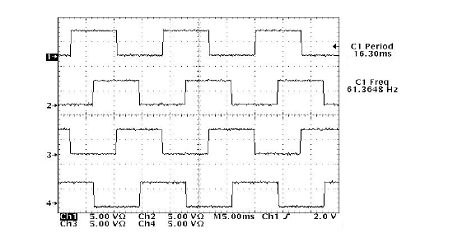

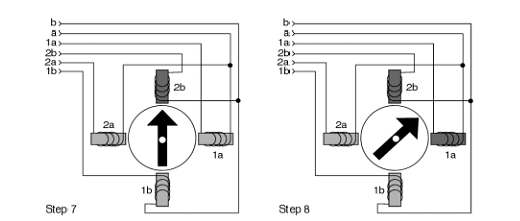

Half Step Mode Table 3. Half Step Sequence

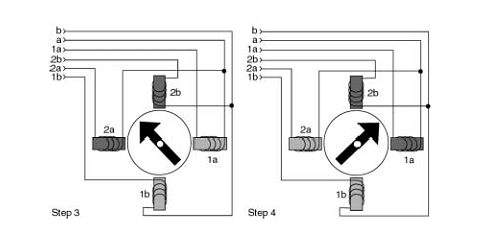

Figure 8. Half Step Sequence

Figure 9. Half Step Sequence

Micro step

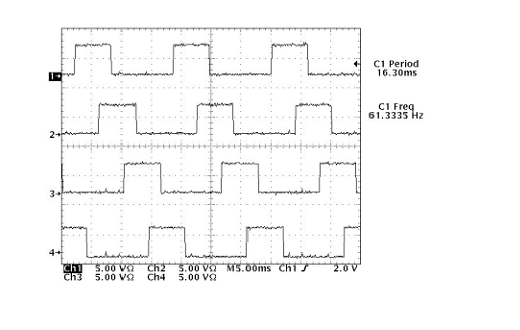

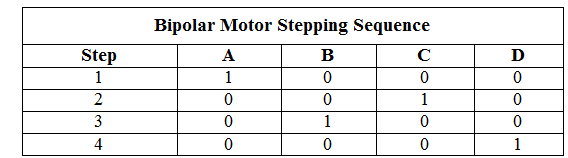

Driving Bipolar Stepper Motors

Advantages

Applications

/* Name : UARTmain.c

* Purpose : Source code for Unipolar full step stepper motor interface with ATMEGA16.

* Author : Gemicates

* Date : 2017-09-09

* Website : www.gemicates.org

* Revision : None

*/

#define F_CPU 8000000UL // Define CPU Frequency e.g. here its 8MHz

#include <avr/io.h> // Include AVR std. library file

#include <util/delay.h> // Include delay header file

#define lcd_clrscr()

#define lcd_puts()

int main(void)

{

int period;

DDRD = 0x0F; // Make PORTD lower pins as output

PORTD=0x00;

period = 100;

// Set period in between two steps of Stepper Motor

while (1) // Rotate Stepper Motor Anticlockwise with Full step sequence; Full step angle 90 degree

{

PORTD = 0x09;

_delay_ms(period);

PORTD = 0x0C;

_delay_ms(period);

PORTD = 0x06;

_delay_ms(period);

PORTD = 0x03;

_delay_ms(period);

}

}

/* Name : main.c

* Purpose : Source code for Unipolar half step stepper Motor interface with ATMEGA16.

* Author : Gemicates

* Date : 2017-09-11

* Website : www.gemicates.org

* Revision : None

*/

#define F_CPU 8000000UL // Define CPU Frequency e.g. here its 8MHz

#include <avr/io.h> // Include AVR std. library file

#include <util/delay.h> // Include delay header file

#define lcd_clrscr()

#define lcd_puts()

int main(void)

{

int period;

DDRD = 0x0F; // Make PORTD lower pins as output

PORTD=0x00;

period = 100;

// Set period in between two steps of Stepper Motor

while (1)

{

// Rotate Stepper Motor clockwise with Half step sequence; Half step angle 45 degree

PORTD = 0x09;

_delay_ms(period);

PORTD = 0x08;

_delay_ms(period);

PORTD = 0x0C;

_delay_ms(period);

PORTD = 0x04;

_delay_ms(period);

PORTD = 0x06;

_delay_ms(period);

PORTD = 0x02;

_delay_ms(period);

PORTD = 0x03;

_delay_ms(period);

PORTD = 0x01;

_delay_ms(period);

}

}

/* Name : main.c

* Purpose : Source code for Unipolar wave drive stepper motor interface with ATMEGA16.

* Author : Gemicates

* Date : 2017-09-10

* Website : www.gemicates.org

* Revision : None

*/

#define F_CPU 8000000UL // Define CPU Frequency e.g. here its 8MHz

#include <avr/io.h> // Include AVR std. library file

#include <util/delay.h> // Include delay header file

#define lcd_clrscr()

#define lcd_puts()

int main(void)

{

int period;

DDRD = 0x0F; // Make PORTD lower pins as output

PORTD=0x00;

period = 100;

// Set period in between two steps of Stepper Motor

while (1)

{

PORTD = 0x08;

_delay_ms(period);

PORTD = 0x04;

_delay_ms(period);

PORTD = 0x02;

_delay_ms(period);

PORTD = 0x01;

_delay_ms(period);

}

}

/* Name : main.c

* Purpose : Source code for Bipolar stepper motor interface with ATMEGA16.

* Author : Gemicates

* Date : 2017-09-11

* Website : www.gemicates.org

* Revision : None

*/

#define F_CPU 8000000UL // Define CPU Frequency e.g. here its 8MHz

#include <avr/io.h> // Include AVR std. library file

#include <util/delay.h> // Include delay header file

int main(void)

{

int period;

DDRD = 0x0F; // Make PORTD lower pins as output

PORTD=0x00;

period = 100;

// Set period in between two steps of Stepper Motor

while (1)

{

PORTD = 0x01;

_delay_ms(period);

PORTD = 0x04;

_delay_ms(period);

PORTD = 0x02;

_delay_ms(period);

PORTD = 0x08;

_delay_ms(period);

}

}